Machining Capabilities

At Buffalo Gear, our machining capabilities extend beyond standard gear manufacturing.

![]() Internal & External Gearing

Internal & External Gearing

![]() Shaping up to 18" O.D.

Shaping up to 18" O.D.

![]() Hobbing up to 40" O.D.

Hobbing up to 40" O.D.

![]() Spur Gears / Helical Gears

Spur Gears / Helical Gears

![]() Worms & Worm Gears

Worms & Worm Gears

![]() Splines / Shafts

Splines / Shafts

![]() Sprockets to 1-1/2" C.P.

Sprockets to 1-1/2" C.P.

![]() Clusters

Clusters

![]() Timing Pulleys (Gear Belts)

Timing Pulleys (Gear Belts)

![]() Sectors

Sectors

![]() Ring Gears

Ring Gears

![]() Pinion Gears

Pinion Gears

![]() CNC Gear Hobbing

CNC Gear Hobbing

![]() CNC Turning

CNC Turning

![]() CNC Milling

CNC Milling

![]() Broaching

Broaching

![]() Key Seating

Key Seating

![]() Precision Honing

Precision Honing

![]() Thread Grinding

Thread Grinding

![]() O.D. & I.D. Grinding

O.D. & I.D. Grinding

![]() Gear Tooth Flame Hardening

Gear Tooth Flame Hardening

![]() Standard / Metric / Special

Standard / Metric / Special

![]() Climate Controlled Inspection Facilities

Climate Controlled Inspection Facilities

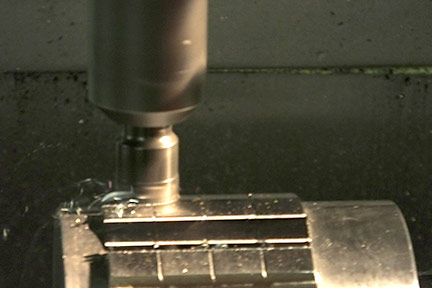

CNC Machining

In order to manufacture high quality precision gear blanks for gears such as spur gears, helical gears, worm gears and pinion gears as well as non-gear related CNC machined products, Buffalo Gear offers an in-house state of the art CNC turning facility with bar-feed capabilities. Also, In-House CNC milling with 4th Axis capability.

Bar-feeding on this machining equipment is ideal for high quality production runs, which allows us to offer you competitive pricing along with a precision machined product.

Advantages of CNC Machining:

![]() Accurate machining

Accurate machining

![]() Precision machined cuts

Precision machined cuts

![]() Minimizes handling

Minimizes handling

![]() Faster turnaround

Faster turnaround

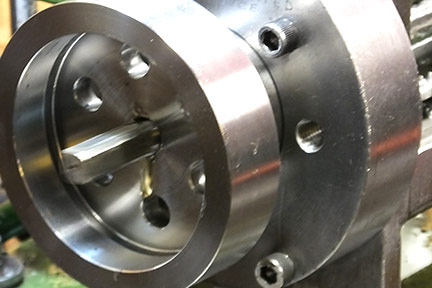

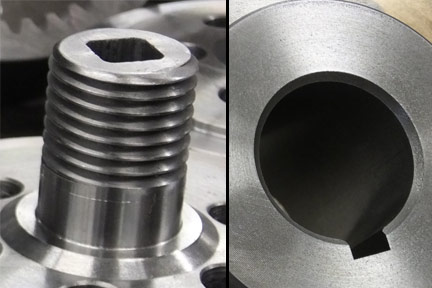

Broaching & Keyseating

Broaching and keyseating are methods used to create the keyways inside of a gear. By offering both gear manufacturing operations, we are able to select the best method for an individual production run. For example, Hydraulic pull style broaching is best used for short production runs.

Buffalo Gear has many standard keyway broaches in stock. Internal splines, hex, square and various irregular shapes can be produced with broaching. We also offer keyseating for larger keyways.

Advantages of Broaching & Keyseating:

![]() High Speed Broaching is cost effective

High Speed Broaching is cost effective

![]() Accurate repetitive size control

Accurate repetitive size control

![]() Most economical way to produce irregular shapes in production runs

Most economical way to produce irregular shapes in production runs

![]() Standard tooling is readily available

Standard tooling is readily available

I.D. Honing

High precision Sunnen manual hones and High Speed Automatic hones provide precision bores with repeatable accuracy; prototype to production.

Advantages of I.D. Honing:

![]() High precision machined parts

High precision machined parts

![]() Can be used with large or small quantities

Can be used with large or small quantities

![]() Assure bore size for ease of assembly

Assure bore size for ease of assembly

![]() Close tolerance is held for shaft and bearing fits

Close tolerance is held for shaft and bearing fits

![]() Superior finishes

Superior finishes

![]() Sunnen technical support available for difficult or unique applications

Sunnen technical support available for difficult or unique applications