Custom Precision Commercial Gears

At Buffalo Gear, we specialize in hobbed and shaped gears. Our vast hob and gear cutting inventory amassed over the years are on hand to save extra tooling charges for our customers.

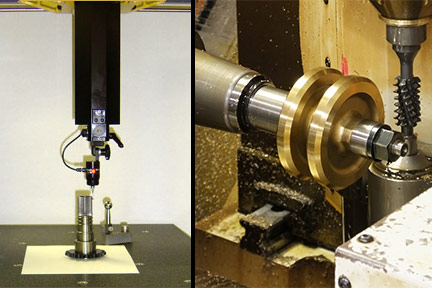

Our state-of-the-art machine shop has the capability to meet your machining needs with CNC Turning, CNC Milling, Gear Tooth Flame Hardening, Thread Grinding, OD and ID Grinding, Key Seating, Broaching and Plating.

Buffalo Gear is here to work with you for all of your gear manufacturing needs. We can reverse engineer and identify stock and non-stock gear forms using our gear testing & analysis equipment.

Let us work with you on your next special gearing project - from prototype to production.

Gear Manufacturing Capabilities

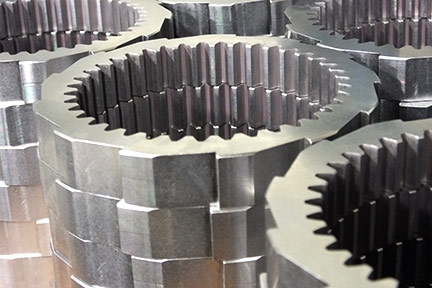

![]() Internal and external gear cutting

Internal and external gear cutting

![]() Standard, metric and special specs gear cutting

Standard, metric and special specs gear cutting

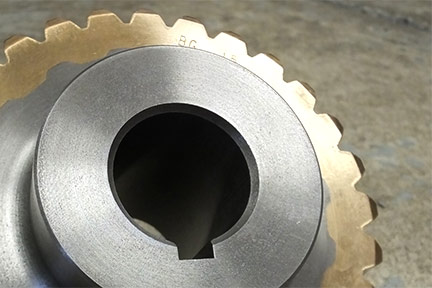

![]() Worm Gears

Worm Gears

![]() Clusters

Clusters

![]() Sectors

Sectors

![]() Splines

Splines

![]() Sprockets to 1-1/2" C.P.

Sprockets to 1-1/2" C.P.

![]() Shafts

Shafts

![]() Pinion Gears

Pinion Gears

![]() Knurling/Crimping Wheels

Knurling/Crimping Wheels

![]() Timing Pulleys and more...

Timing Pulleys and more...

Gear Materials & Sizes

![]() Stainless Steel

Stainless Steel

![]() Carbon

Carbon

![]() Alloy steels

Alloy steels

![]() Bronzes

Bronzes

![]() Brass

Brass

![]() Aluminum

Aluminum

![]() Iron

Iron

![]() Various Exotics

Various Exotics

![]() Plastics and Fibres

Plastics and Fibres

You can also provide your own blanks.

Buffalo Gear manufactures gears from 3/8" to 40".

Our D.P. range is from 3 to 120.

Climate Controlled

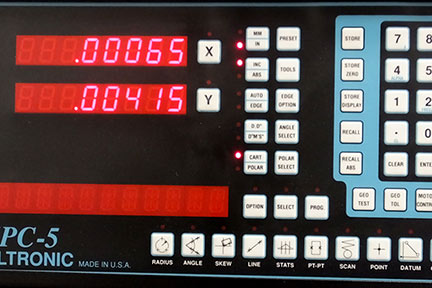

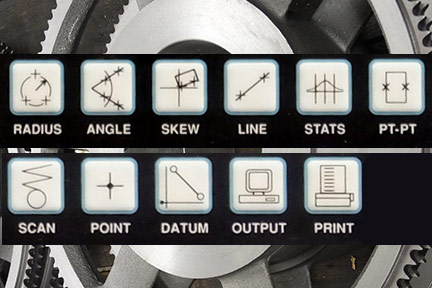

Gear Inspection

Our climate controlled gear inspection facility is a vital part of quality control and provides a clean environment for certified gear testing equipment used to chart gears.

It is essential for gauging accuracy and needed to maintain and assure quality CNC machined parts.

Buffalo Gear can identify and reverse engineer gear forms using our gear testing equipment and computer generated gear applications.

Advantages:

![]() Test integrity of machined parts

Test integrity of machined parts

![]() Ensure high quality and high precision gears

Ensure high quality and high precision gears

![]() Maintain integrity of gauges and gear test equipment to controlled certified standards

Maintain integrity of gauges and gear test equipment to controlled certified standards